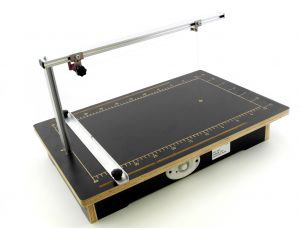

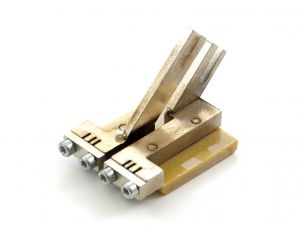

Knives for polystyrene and sponges

Knives for polystyrene and sponges allow for a clean cut of these surfaces without fraying and crumbling, which allows you to keep clean on the construction site and in the company. What is the best knife for polystyrene? During construction work, there is nothing better than the AT-250 burnout for all window and bay window treatments with a grooving machine, it allows you to cut tunnels and other places for cables, conduits in the walls, floors and culverts. However, if you deal with hobby and floristic cutting of 3D letters - spatial advertising ones, opt for the D3 table or even the manual version of the H2 knife. How to cut foam or sponge? The best model for such works is the D3 table with resistance wire, but when cutting boards into smaller ones, the AT-250 model should be chosen. What materials are best for cutting? EPS, i.e. expanded polystyrene - irrespective of the hardness of styrodur XPS i.e. extruded polystyrene - irrespective of the hardness of the sponge, e.g. polyurethane foams, foils out of insulating glass, EVA foils and derivatives of pipe insulations In which industries we most often use these knives? construction - cutting cutting out hobby - DIY advertising stucco - cornices, figures and strips for individual orders and production floristry - filling seams - fixing