Polyurethane adhesives

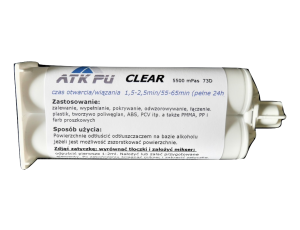

PUR adhesives, basically based on polyurethanes, are abundant due to the fact that they are products that can be easily modified to the desired properties. The application and types are briefly discussed below. Types of polyurethanes: The main division into one-component and two-component, and flexible or rigid (semi-rigid) One-component flexible - after setting, we obtain a flexible and more or less soft form like rubber. Often confused with silicone, even though it is a completely different base. Mainly used in the automotive industry and industry for bonding and sealing instead of silicones, but for several years there have been even better products, i.e. MS polymer adhesives, which have eliminated their disadvantages (the exception is Kemiskol T055 fast automotive seals). One-component hard - semi-rigid - general use in construction and industry - often replaced by two-component versions or switching to methacrylic adhesives. Two-component flexible polyurethane adhesives - they are pourable as a liquid polyurethane for sealing and pouring surfaces, but also for joining two separate materials, and these are versions PU5 and PU9 - with different flexibility and setting time. Two-component hard and hard-elastic - we mainly focus on the latter, because hard is used less often. The versions with high expansion include ATK PU16 and 021. The former is automotive polyurethane with very good strength properties and strong bonding to the ground. The ATK PU 021 version is a version for large surfaces for use in gluing and pouring. What do we glue with polyurethanes? The multitude of versions allows for such a selection that we can glue any material that comes to the head, i.e. metals, stones, ceramics, cork, composites, glass, painted surfaces, wood, brick and plastics (here, in principle, an exception as in most surfaces, i.e. without POM , PTFE and PE) when bonding PP, we use ATK 822 primer. Manufacturer of polyurethane adhesives. In the ATK series, we use only proven versions of the Italian and German manufacturers, with particular emphasis on the automotive industry (PU 16 and 021). Are glue and resin the same products? No. Resin is always thin and takes into account the cohesive forces. Adhesives must combine both adhesions and cohesions and often cannot be poured over the surface through a dense form, and gluing takes place by pressing two materials. Pros and cons of PU adhesives. usually these are low-priced products, although the initial binding may be even in a few minutes - but it is always taken 24 hours to fully bind. often required primer-primer depending on the material, eg ATK 822 for plastics and metals, P200 for materials such as metals, rough and absorbent. in the case of large production works, one should remember about working clothes and efficient ventilation.

.jpg)