Cyanoacrylate adhesives

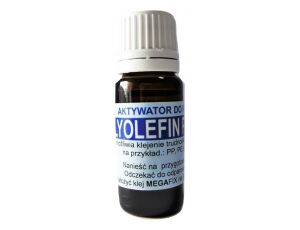

Cyanoacrylate adhesives properties Cyanoacrylate adhesive has a wide range of applications when bonding various materials due to the speed of gluing and ease of application. These are solvent-free adhesives operating on the principle of cutting off the air, and then the bonding takes place, which gives rise to an elevated temperature, locally up to 80 degrees. These are adhesives resistant to water and various chemicals, such as oils, greases and gasoline, therefore after gluing two materials, such as a rubber hose, it ensures air tightness and tightness for car chemicals. It should be remembered that these are contact-contact adhesives, i.e. the surface should fit. After gluing, the elements are as flexible as the material, however, it should be borne in mind that despite their small thickness, a slight hardening may occur with very flexible materials; (especially if we exceed the gap / amount of glue above 0.05 mm). The rule is that the smaller the gap, the better, and even with materials that are pressed tightly, you can put under the press - then we use the rarest version ATK FIX 06. If we glue absorbable elements, at an angle or with larger gaps, choose a slightly dense version or even dense ATK FIX 54. remembering that the setting time will be extended from 3-5 seconds to 20-30 seconds (if we do not use activator C as an accelerator). What do we use cyanoacrylate adhesives for? We can glue metals, plastics - with primer also PP and PE, wood, glass, leather, stone and rubber; that is, we will stick elements such as: a shelf in a refrigerator, a gasket in a car, a torn tarpaulin, and plastic moldings in the industry. However, if we want to repair a broken handle, which is 2 mm thick, then ATK FILL powder should be used as a filler to strengthen the joint after butt gluing. Remember to always degrease the surfaces when gluing and apply as little glue as possible. Too much excess that will flow out immediately, wipe it off - pressing it all the time. If you will glue long surfaces, e.g. a seal, apply the product for a distance of 3-5 cm and press it to the bond - continue the glue in this way. Additives for cyanoacrylate adhesives: There are 3 additives for CA adhesives and they are: Glue filler - ATK FILL - a form of loose powder, with which we strengthen the surface from the outside and fill gaps and defects in the surface. after bonding, we obtain a hard surface that can be filed or sanded. Remember to apply in layers of approx. 1 mm so that the glue can be absorbed into the powder. Activator for glue (Activator C) - accelerates the hardening of the glue, especially flashes, and reduces the bonding time between surfaces on materials where bonding would take place 20-30 more seconds as PVC. The activator is in the form of a spray or liquid. Primer for polyolefins and silicone rubbers - a primer that allows gluing materials, the so-called difficult-to-bond materials such as PP, PE, POM and PTFE, and for rubbers with additives or on silicone bases. in the form of a liquid to wipe the surface for 1-2 minutes. before applying.