How to repair plastic that is not weldable with uflex plastic?

The next generations of the resulting mixtures of plastics, containing increasing amounts and additives, e.g. talc, glass fiber, cellulose or metal, are becoming more and more complicated in the repair process.

The high content of fillers in the volume of the element causes the formation of a barrier that makes it impossible to connect the material, e.g. a bumper with another material that we want to use for repair. A very common symptom, which indicates a high filler content, is the formation of a white coating after the exemplary binder is detached from the welded surface.

In such cases, the standard method of welding with traditional hot air binders will unfortunately not work. It is necessary to use a special universal U-Flex binder applied by heat sealing.

We will show the application of the U-Flex binder on the example of the repair / "transplant" of the front bumper from the American version of the 2016 Ford Fusion made of TPO material.

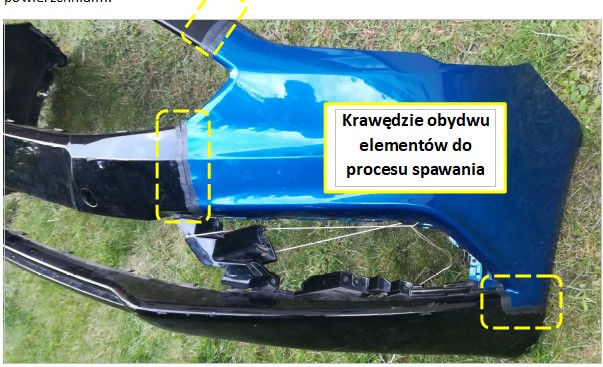

Donor (Blue) and Recipient (Black) bumper view - 2016 Ford Fusion

The original bumper (Black) was so badly damaged that it was necessary to transplant a fragment of the donor's bumper (Blue) and weld it in the right place.

The first stage of repair was to select the appropriate binder for the repair. Not having the knowledge that it is non-weldable yet, a series of adhesion tests of all PP-based binders were performed. TPO blend has a very similar composition as PP + EPDM, hence the above selection.

Unfortunately, all tests on mixtures such as: PP, TPO, PP + T40, PP + EPDM, PP + ET2X, PP-U or PP + EM1 gave the same effect - the test strip of adhesive could be easily torn off the bumper surface and remained after him a gray trail.

Tests of adhesion of binders on the inner surface of the Ford Fusion bumper

Such results of the strength tests of binders made it necessary to use the universal U-Flex mixture to repair the bumper. This blend is ideal for materials based on Polypropylene (PP), as is the case here.

Before starting the actual process of applying the U-Flex binder, the missing fragment of the bumper from the donor element was cut off and fitted. The fit of the elements should be as good as possible so as not to create empty gaps between the joined surfaces.

View of the matched fragments of the donor and recipient Ford Fusion bumper

The actual process of repairing the material with the use of the U-Flex mixture is called "heating" and we perform it using the "Hot-Iron" welding machine available at Ataszek.pl.

The heating of the binder consists in plasticizing the U-Flex binder by applying it to the copper sealing flange until it is completely plasticized and spreading it over the surface of the crack.

We perform the U-Flex welding process according to the following steps:

1. Clean the surface around the crack / edge of the joint with an IPA solution (isopropyl alcohol degreaser)

2. Grind the surface with coarse-grained sandpaper, e.g. P80 on a roller to obtain a rough surface for better adhesion with the binder

Coarse sanding of surfaces with a roller with sandpaper to remove oxides and residues of primer / varnish

3. We mill the groove in the place of the fracture / connection using a round / flame cutter. The groove should have a semicircular shape with rounded edges - Sharp edges cause notches where the U-Flex may detach from the welded surface.

Milling a semicircular slot with a flame cutter. The groove has no rounded radii yet

4. Once again, we clean the entire surface on which we will apply U-Flex.

5. We start the welder by connecting to electricity and set the temperature range between 80-90% of the range. We wait about 10 minutes for the foot to heat up to the appropriate temperature.

6. Heat one-sidedly a short section of U-Flex, ie about 3-4 cm, by moving the foot on the surface of the binder until it becomes plastic.

Plasticization of U-Flex by driving the tip of the welding machine over the surface of the binder

7. Then turn the binder 180 degrees and spread it over the surface of the groove / around the surface. Spreading is done by rubbing the binder with light movements to the sides with the use of minimal force, so that the binder is spread under the influence of plasticizing the material with temperature

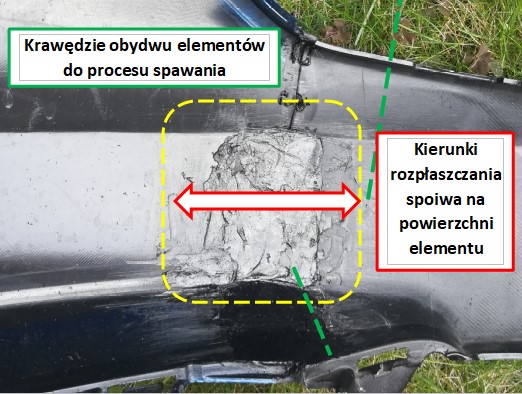

Heated U-Flex binder into the space of the milled groove and around the surface

Important! Since the U-Flex binder binds only superficially with the repaired material, the basis for good adhesion of the binder to the repaired material is the perfect cleaning of the surface of all inclusions (dust, plastic pieces, dirt). A poorly cleaned surface will result in a faulty connection!

For example, a correctly welded U-Flex joint / surface is shown in the photo below:

Correctly distributed U-Flex binder on the joining of the Ford Fusion bumper fragments

For the initial connection of the bumper fragments that are to be fitted together, you can use welded steel RS28 type tabs welded into the material with the SP-1 stapler.

In the case of heavy elements, it is necessary to compact the number of staples to obtain the appropriate strength of the connection.

Serial sinking of steel staples at the junction of the bumper fragments with the SP-1 stapler

The final repair effect by welding U-Flex binder on all joints of the bumper parts to the Ford Fusion

Autor: Adam Dmitriew (@6Nylon)

Comments