Hot resistance wire cutting

Hot cutting - what is important?

When we want to cut materials hot, we usually take into account two factors: aesthetics, i.e. correctly cut edges, and precision - i.e. a perfect cut to a specific size.

Below the text, you can see a detailed video presentation.

Resistance wire for cutting polystyrene and more.

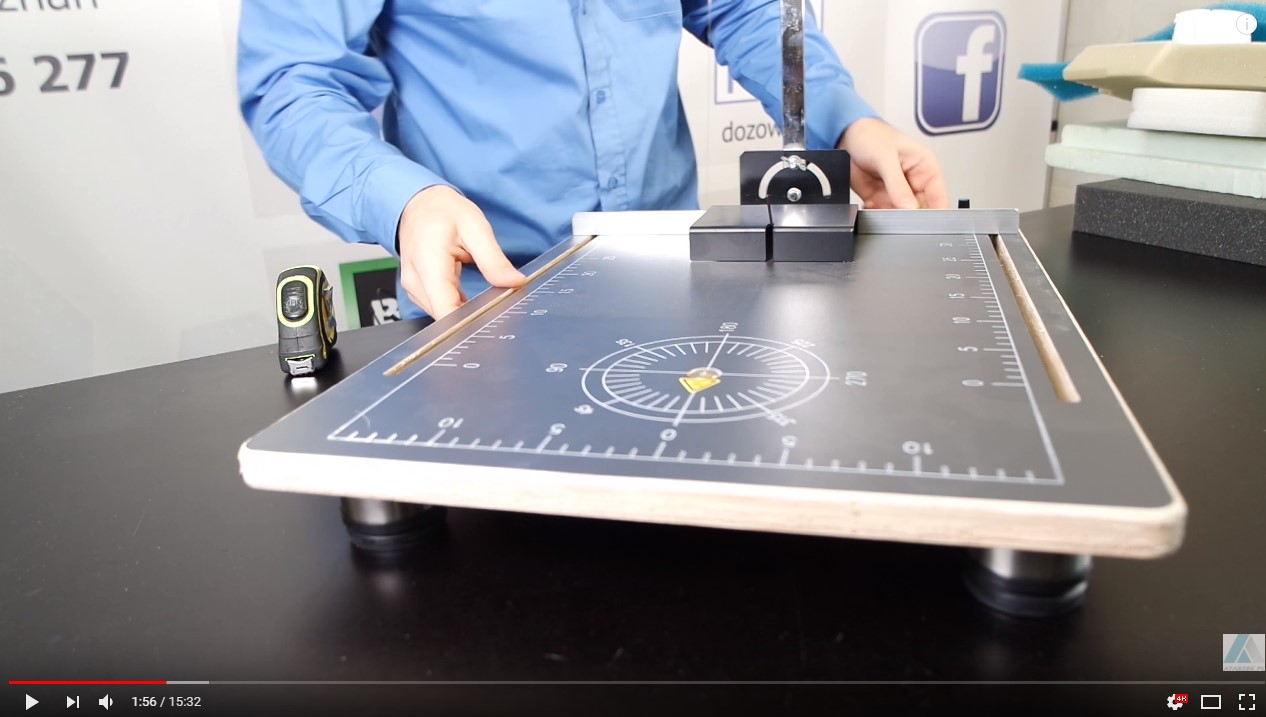

Today we will not focus only on polystyrene, although it is mainly used most often. The device presented in the video (Thermal knife with a D3 table top) will also cut foams, styrodur and sponges. It has adjustable power. The table itself is light and handy. It can be easily moved from place to place. We can adjust the feet, which facilitates positioning on different planes. The most important advantage, however, is the ability to adjust the cutting angle from 30 to 90 degrees. Depending on the material being cut, we can influence the tension force of the wire through an adjustable knob. A guide has also been considered, which you will learn more about by watching the video below.

The D3 warm knife provides adjustment of the blade tension and cuts at the right angle.

We test cutting with resistance wire on plastics.

At the beginning, we set half the power, which is about 250 degrees. We will use a 0.2 wire. Of course, you can use a thicker wire, remembering to adjust it to the appropriate structure of the material. The first test is polystyrene cutting. The cutting is precise, without any smoke or burns.

Aesthetic and smooth cut without burns on the example of polystyrene.

Another element is stiff foamed foam. We cut without temperature intervention, so still on the same settings. The effect is similar to cutting polystyrene. You cannot see any burnt parts even with increasing temperature. We cut smoothly even at different angles and in various shapes. Thanks to this, we can use previously prepared templates.

Cutting the foam does not cause any problems, even forming any shape.

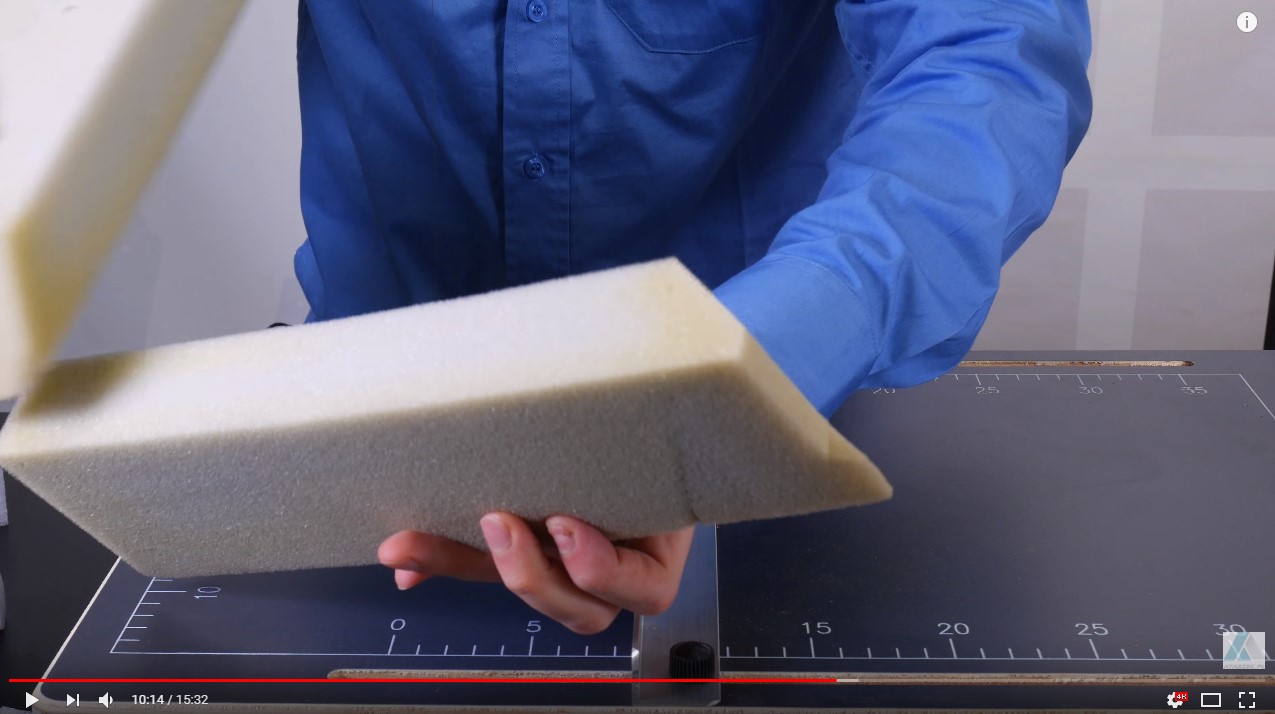

The sponge is also not a problem, but you feel a slight resistance while cutting, so to speed up the cutting - slightly increase the temperature. Still no burns on the edges.

Cutting the sponge without unnecessary smoke and burns. See the effects by watching the video.

Upholstery sponge, much denser and denser material than the previous one. We set 3/4 of the power of the thermal knife. We use the guide rail for convenience to show its operation. The surface is perfect and not melted. The next attempt is carried out at an increased temperature (power 90%), but it still does not burn the material and only speeds up the cutting. Of course, remember to maintain the optimal temperature. Test it!

Using the rails, we cut simple and aesthetic.

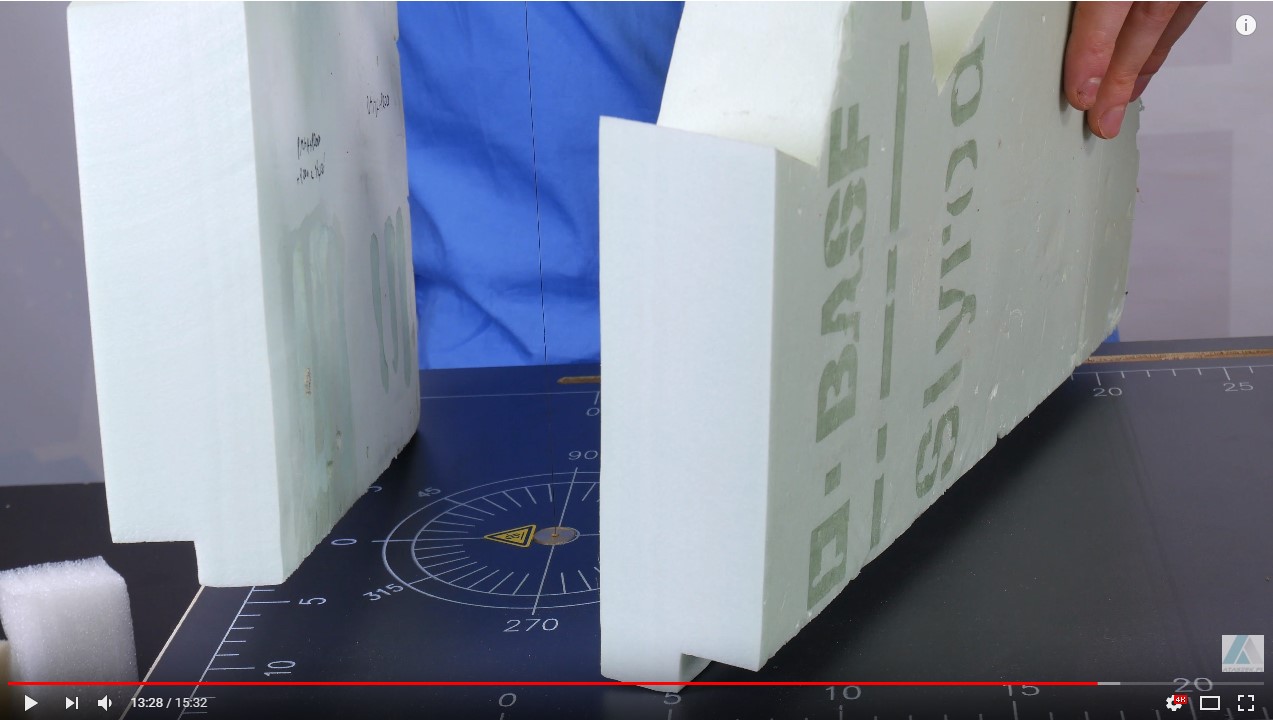

Finally, styrodur, which is a very hard material, lands under the knife. In the video you will see that the cut is perfectly smooth, without unnecessary scraps or ends. By using the guide, you will further improve your effect.

The knife can handle even such a hard material as styrodur.

Resistance Wire Cutting - Video

Comments