Cyanoacrylate adhesives - types and application

You should know that in addition to using cyanoacrylate adhesives alone, there are various additives on the market - which are sometimes necessary when using cyanoaryl adhesives. They usually speed up and help to increase the efficiency of our gluing.

These are:

- degreaser for plastics - used for surfaces that need to be cleaned or washed. We have two versions available - alcohol and acetone (aggressive version). It copes well with contamination such as grease, grease

- ATK FILL powder - we use for hard materials - e.g. hard with hard, or hard with semi-elastic,

- activator C - accelerator, used between surfaces or after gluing,

- PP PE primer - preparation for surface activation,

The most commonly used cyanoacrylate adhesives are ATK FIX 01 and ATK FIX 06 - see detailed information.

In the 43-minute guide, you will learn about all the most important cyanoacrylate adhesives and additives that are the basis for a successful gluing.

Before each gluing, we must degrease the surfaces with a cloth or paper until we stop noticing contamination. Before you use it, check if there is any reaction with the glued material,

We do not use anything else in basic gluing. Then we reach for the glue and apply it in the right amount. You can see an example of gluing in our guide. (See the trailer)

During our guide, we carry out standard PVC-Rubber bonding - (we will show you a more extensive guide soon)

It is a contact adhesive, so - we apply a slight pressure, and then the whole thing should spread. ATK FIX 06 - is a version of the adhesive, where after a few minutes we have everything ready.

Cyanoacrylate adhesives are universal - in this guide we glued PVC rubber. (tarpaulin material)

Remember! When using glue - use protective glasses and foil gloves.

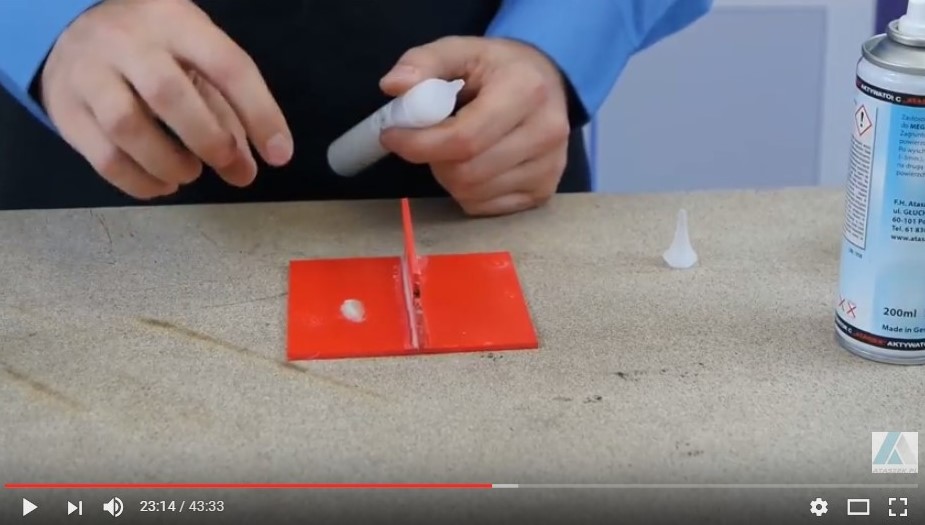

The second example of adhesive application is the use of cyanoacrylate adhesive with a reinforcing powder and Activator C accelerator.

We always use the ATK FILL powder last - not the beginning! If we use an activator between surfaces - we spray on one of the surfaces and apply glue on the other. We showed it well on the video, so don't worry that you don't understand something. Just check out our guide at the bottom of this post - and see how to glue. As for the gaps, we use ATK FILL powder here - we put the glue into the appropriate surface and then into the grooves or gaps - our defects - we use a powder filling and then pour cyanoacrylate glue again. The powder solidifies within a dozen or so seconds. If we poured too much powder, don't worry - we can use the activator.

The use of filling powder significantly facilitates and strengthens the glued elements.

Of course, these are just a few basic examples of how to use cyanoacrylate adhesives with additives - be sure to watch the entire 40-minute long guide. You will learn from it what additional possibilities gives us the use of cyanoacrylate adhesives.

SEE THE TRAILER BELOW - OR SIGN UP FOR THE LIST AND WATCH THE ENTIRE

![]()

Comments